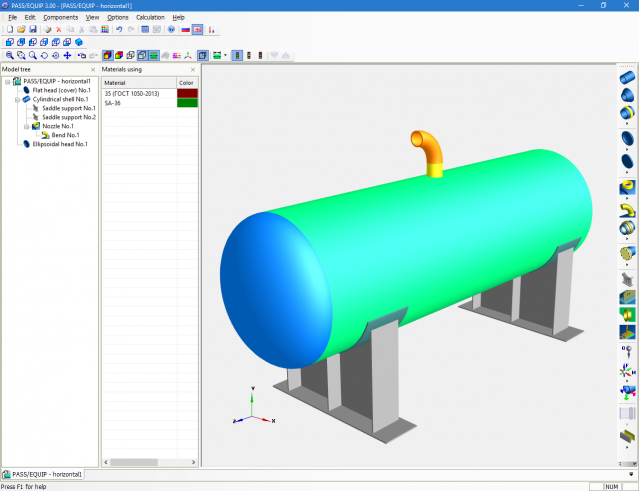

PSRE Co., a developer of smart simulation and sizing software for piping and equipment design, has chosen the C3D Toolkit to power 3D modeling in its PASS/EQUIP program. The software conducts comprehensive structural pressure vessel analysis. The C3D Modeler geometric kernel is responsible for accurately modeling 3D parts. The accompanying C3D Converter data exchange module exports models in ACIS, IGES, Parasolid, and STEP formats.

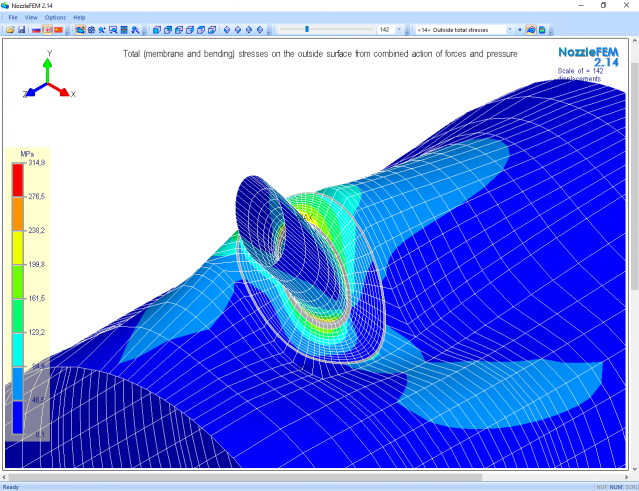

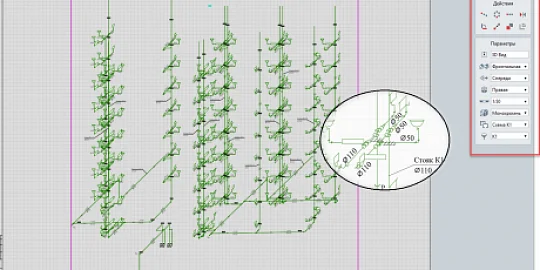

To evaluate bearing strength, PASS/EQUIP provides strength and stability analysis for horizontal and vertical vessels, storage tanks, and columns, as well as shells, tubes, and air-cooled heat exchangers under static and seismic loads. The software uses finite element analyses of vessel nozzles for estimating the stress, stiffness, and allowable loads.

To create 3D models, PASS/EQUIP performs Boolean operations and mass properties analysis on nozzle-to-shell junctions, flanges, heat exchangers, and other parts. All these elements are created by the C3D Modeler kernel, in particular fillets with complex shapes. Based on the shells constructed, the software generates the meshes necessary for FEA simulation.

Alexey Timoshkin, CIO of PSRE Co:

Yuri Kozulin, Head of C3D Modeler department at C3D Labs:

“To meet the needs of PSRE Co., we accelerated the performance of our C3D Modeler and increased the reliability of operations PASS/EQUIP told us that they needed. We improved shell truncation, extrusion, and revolution; the construction of parting lines; and the projection of curves. In addition, we developed a new code sample that does direct shell modeling with parting lines.”

About PSRE Co.

PSRE Co. is a leading developer of smart simulation and sizing tools for every piping and equipment engineer and designer. The company has 40 years of experience in developing tools for calculating strengths and hydraulics, and in designing heat insulation and automatic discharge systems. Their software products are de facto industry standards in Russia, and are used by over 1,200 companies in Europe and Asia.

For more information about PSRE, visit https://www.passuite.com

“PASS/EQUIP has a fixed set of parametric models being calculated by the finite element method. We decided on C3D Toolkit, because it could create arbitrary models. It allows us to consider defining equipment cases more accurately, to reduce edge effects, and calculate the parameters for closely-spaced nozzles. For FEA purposes, we must focus on geometric details, because the accuracy of modeling directly affects the calculated result.”